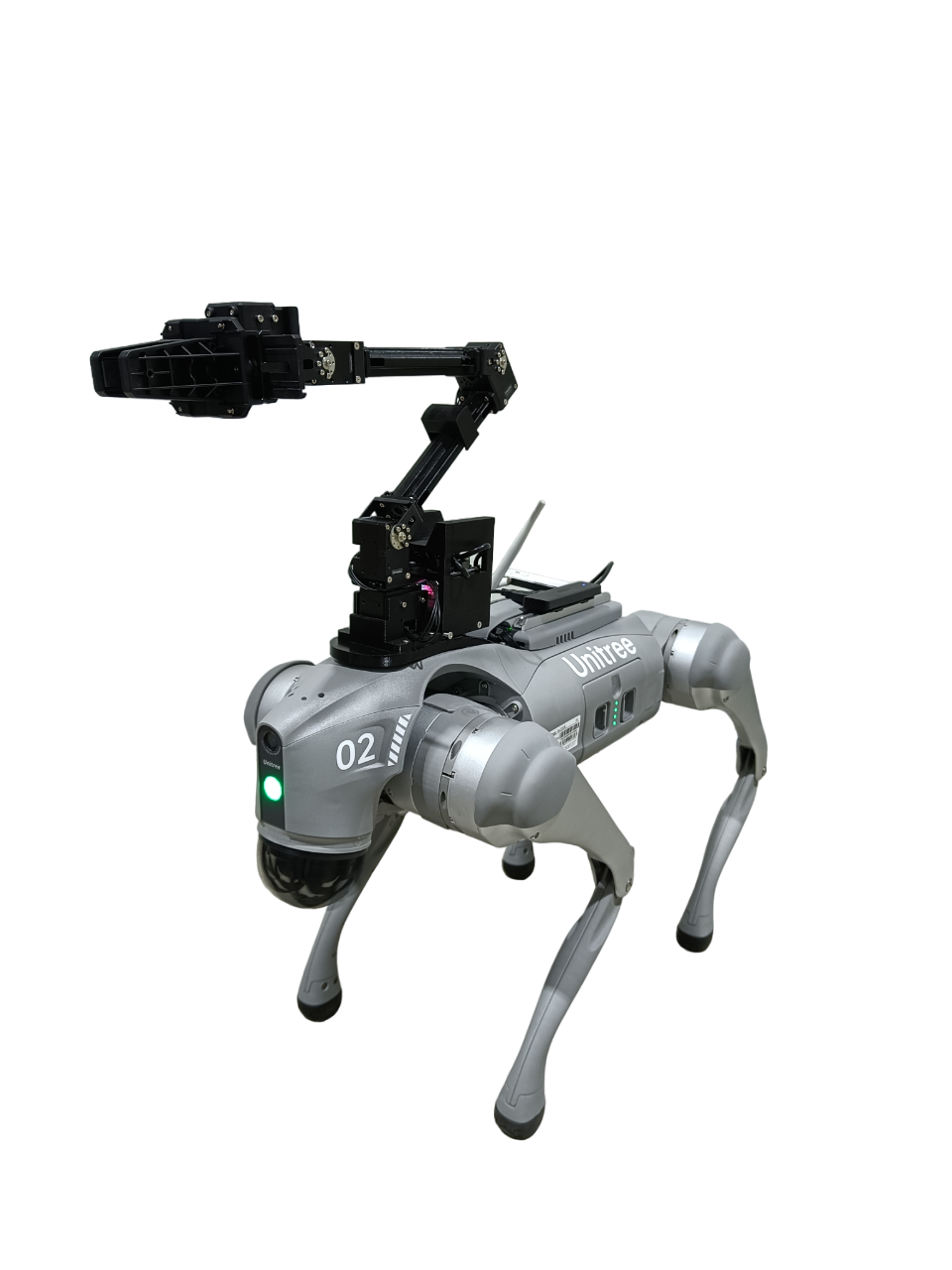

Open Manipulator X ROS Control

Openmanipulator Home Pose |

Openmanipulator Ready Pose |

Start Open manipulator X custom ROS driver

ros2 launch go2_moveit system_openmanipulator.launch.py

Note

This should always be running when using the provided moveit and/or joint trajectories

Launch moveit and state publisher

ros2 launch go2_manipulation system.launch.py

Test the driver

ros2 action send_goal /open_manipulator/joint_trajectory_controller/follow_joint_trajectory control_msgs/action/FollowJointTrajectory -f "{

trajectory: {

joint_names: [joint1, joint2, joint3, joint4],

points: [

{ positions: [0.1, 0.1, 0.1, 0.1], time_from_start: { sec: 2 } },

{ positions: [-0.1, -0.1, -0.1, -0.1], time_from_start: { sec: 4 } },

{ positions: [0, 0, 0, 0], time_from_start: { sec: 6 } }

]

}

}"

Home position (Must be done when turning off)

ros2 action send_goal /open_manipulator/joint_trajectory_controller/follow_joint_trajectory control_msgs/action/FollowJointTrajectory -f "{

trajectory: {

joint_names: [joint1, joint2, joint3, joint4],

points: [

{ positions: [0.0, -1.4, 1.2, 1.2], time_from_start: { sec: 2 } },

]

}

}"

Close gripper (Must be done when turning off)

ros2 action send_goal /open_manipulator/gripper_controller/follow_joint_trajectory control_msgs/action/FollowJointTrajectory -f "{

trajectory: {

joint_names: [gripper],

points: [

{ positions: [1.0], time_from_start: { sec: 2 } },

]

}

}"

Open gripper

ros2 action send_goal /open_manipulator/gripper_controller/follow_joint_trajectory control_msgs/action/FollowJointTrajectory -f "{

trajectory: {

joint_names: [gripper],

points: [

{ positions: [-1.0], time_from_start: { sec: 2 } },

]

}

}"

Precautionary Measures

• Be careful with certain go2 actions such as wallow. This will cause the robot to flip over onto its back damaging the arm.

• Power off the GO2 correctly when power is low from the battery.

• Ensure the Open manipulator is in home position before killing its driver, otherwise it will fall.

Known Issues

• Open Manipulator not responding

• This may occur due to wrong joint positions of the dynamixels.

• The solution is to either power cycle the entire robot or only the open manipulator arm ensuring that the open manipulator’s driver is turned off.

Safety Guidelines: Robotic Manipulator

When deploying robotic manipulators, it is imperative to prioritize safety procedures to mitigate risks and ensure secure operations. The following guidelines delineate key safety measures when working with robotic manipulators.

Work Area Safety

Maintain a clean and well-organized work area. Cluttered or inadequately lit spaces can impede the proper functioning of sensors and hinder precise manipulation.

Avoid operating robotic manipulators in hazardous environments, such as those containing corrosive substances, extreme temperatures, or sharp objects that may damage the manipulator.

Ensure that only authorized personnel are present in the vicinity during manipulator operation to prevent interference and ensure a safe working environment.

Electrical Safety

Ensure the manipulator’s power system adheres to electrical safety standards. Regularly inspect and maintain power components to prevent malfunctions.

Implement safeguards to protect the manipulator from adverse environmental conditions, such as exposure to moisture or extreme temperatures.

Regularly inspect power cables and connections, promptly replacing damaged components to minimize the risk of electrical issues.

Manipulation Safety

Implement collision detection systems to prevent unintended contact with objects, humans, or other equipment during manipulation tasks.

Define and enforce safety zones around the manipulator’s workspace to minimize the risk of unintended interactions with personnel or other objects.

Regularly calibrate and test the manipulator’s sensors and systems to ensure precise and reliable performance during manipulation tasks.

Emergency Response

Install an emergency stop mechanism to swiftly halt manipulator operation in unforeseen circumstances or emergencies.

Clearly mark and communicate emergency stop locations within the manipulator’s operational area.

Conduct regular emergency response drills to ensure personnel are familiar with procedures for handling unexpected situations during manipulator operation.

Data Security and Privacy

Implement robust cybersecurity measures to safeguard the manipulator’s control systems and data from unauthorized access or manipulation.

Ensure compliance with privacy regulations when collecting, storing, or transmitting data captured by the manipulator’s sensors.

Human Interaction Safety

Integrate sensors and communication systems to detect and respond to the presence of humans in the manipulator’s vicinity.

Clearly communicate the manipulator’s operational status and intentions using visual and audible signals to alert nearby individuals.

Establish protocols for safe human-robot collaboration, particularly in shared workspaces where manipulators are in operation.

Residual Risks

Despite the implementation of safety measures, certain residual risks may persist. These include:

Impairment of sensor functionality.

Risk of collisions during complex manipulation tasks.

Cybersecurity vulnerabilities.

Unintended human interactions due to unforeseen circumstances.

Robotic manipulators are sophisticated technologies that demand correct usage to avoid accidents and ensure a secure environment. Please adhere to proper procedures diligently, prioritizing both precision and safety.

Safety Guidelines: Autonomous Robot

When deploying autonomous mobile robots, prioritizing safety procedures is essential to prevent accidents and ensure secure operations. The following guidelines outline key safety measures when working with an autonomous mobile robot:

Work Area Safety

Maintain a clean and well-lit work area. Cluttered or poorly illuminated spaces can impede the proper functioning of sensors and navigation systems.

Avoid operating autonomous mobile robots in explosive atmospheres, such as areas with flammable liquids, gases, or dust. The robot’s components may pose a risk in such environments.

Keep bystanders and unauthorized personnel at a safe distance during robot operation to prevent interference with autonomous navigation.

Electrical Safety

Ensure the robot’s power system adheres to electrical safety standards. Regularly inspect and maintain power components to prevent malfunctions.

Implement mechanisms to protect the robot from adverse weather conditions, such as rain or wet environments.

Regularly inspect power cables and connections and replace damaged components promptly to minimize the risk of electrical issues.

Emergency Response

Install an emergency stop mechanism to quickly halt the robot’s operation in case of unforeseen circumstances or emergencies.

Clearly mark and communicate emergency stop locations throughout the robot’s operational area.

Conduct regular emergency response drills to ensure personnel are familiar with procedures for handling unexpected situations.

Data Security and Privacy

Implement robust cybersecurity measures to protect the robot’s control systems and data from unauthorized access or manipulation.

Ensure compliance with privacy regulations when collecting, storing, or transmitting data captured by the robot’s sensors.

Human Interaction Safety

Integrate sensors and communication systems to detect and respond to the presence of humans in the robot’s vicinity.

Clearly communicate the robot’s operational status and intentions using visual and audible signals to alert nearby individuals.

Establish protocols for safe human-robot collaboration, especially in shared workspaces.

Residual Risks

Despite the implementation of safety measures, certain residual risks may persist. These include:

Impairment of sensor functionality.

Risk of collisions in crowded or dynamic environments.

Cybersecurity vulnerabilities.

Unintended human interactions due to unforeseen circumstances.

Autonomous Mobile Robots (AMR) are advanced technologies that require correct usage to avoid accidents and ensure a secure environment. Learn and follow the proper procedures diligently; prioritize both quality and safety.